Quality standards of TM "Altep": Quality of billets

Standard 1: Quality of billets.

Do you want to choose a high-quality solid fuel boiler that will last more than 10 years?

Then you need to know what factors affect the reliability and durability of the equipment.

The boiler is based on a metal heat exchanger, the blanks for which are made of steel with a thickness of 6-8 mm. The heat exchanger can be leak-proof and efficient only if the metal is accurately cut to size and of the right quality and the workpieces are properly prepared before welding.

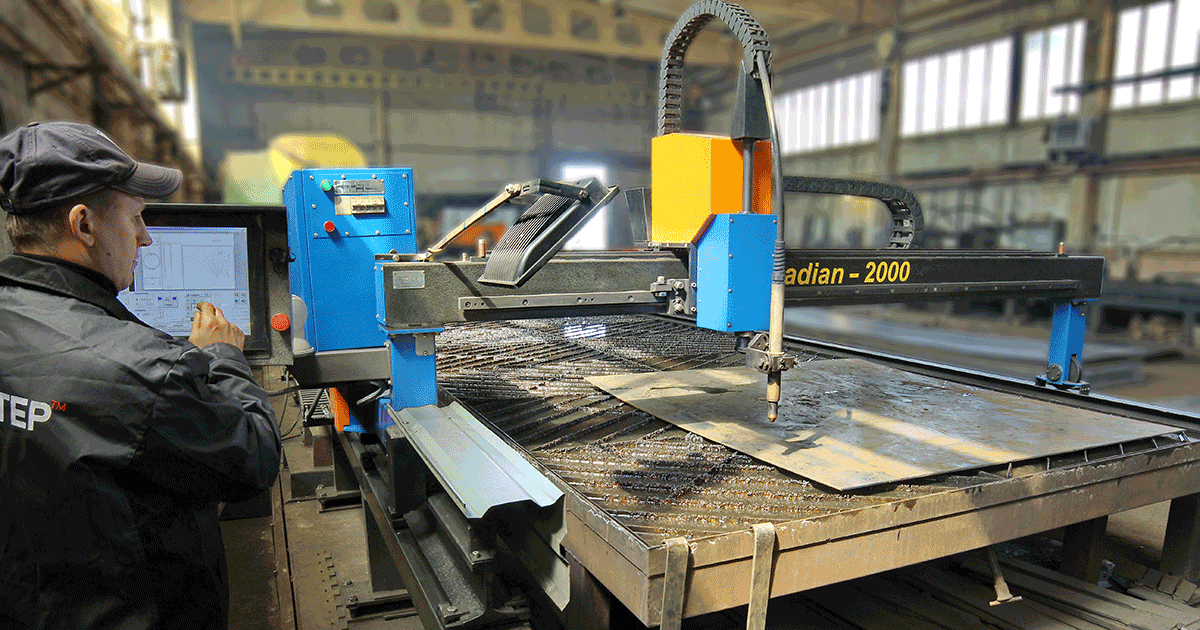

High-quality production of blanks is ensured by plasma and laser cutting of metal on modern CNC machines. Further processing of parts is carried out on modern high-precision sheet bending machines. All workpieces are subject to quality control. The processed parts are formed into kits and transferred to the welding shop. Thus, after welding, we get a hermetic heat exchanger with the correct geometry that meets the declared technical documentation.