Solid fuel boiler TRIO UNI Plus

![Boiler TRIO UNI Plus - [2] Boiler TRIO UNI Plus - [2]](https://altepworld.com/storage/products/images/big/ANT1jAL7tHaGHm7bFc1XZt6RuuMdhN7Rv5JHLHTW.jpg)

![Boiler TRIO UNI Plus - [3] Boiler TRIO UNI Plus - [3]](https://altepworld.com/storage/products/images/big/7ATAGZeDivcJU83XtzX21hL33CIgpMc1UOAIpzBe.png)

![Boiler TRIO UNI Plus - [4] Boiler TRIO UNI Plus - [4]](https://altepworld.com/storage/products/images/big/h5O8GQPXYGi54c5NH2JXzXe0VMxFxR8IJbtaSaNm.png)

![Boiler TRIO UNI Plus - [5] Boiler TRIO UNI Plus - [5]](https://altepworld.com/storage/products/images/big/Vm725MrVmo5Vmh53iqDRNPdXRzN5yApJhMlqO2IO.png)

![Boiler TRIO UNI Plus - [6] Boiler TRIO UNI Plus - [6]](https://altepworld.com/storage/products/images/big/Qy2LF80tYVBsnyY3ncMFyvVpU0eSAa6PrO2XAIjP.png)

![Boiler TRIO UNI Plus - [7] Boiler TRIO UNI Plus - [7]](https://altepworld.com/storage/products/images/big/kqJzxGvtGWBdX1DoCtnLgNWmk7kySdyND7Z3MTlj.png)

![Boiler TRIO UNI Plus - [8] Boiler TRIO UNI Plus - [8]](https://altepworld.com/storage/products/images/big/2JNX5plOxfbermkp5t2mGbm6fWSRrB0fIJUy16Ah.png)

![Boiler TRIO UNI Plus - [9] Boiler TRIO UNI Plus - [9]](https://altepworld.com/storage/products/images/big/0k1hdNW0LSZ0h7gkG0k9pu2ayThf2Ibwk4qt58Yi.png)

![Boiler TRIO UNI Plus - [10] Boiler TRIO UNI Plus - [10]](https://altepworld.com/storage/products/images/big/AKm4jq57Ch9bfRNl7OiWWmUa7reXTb2SNaWUODZ8.png)

![Boiler TRIO UNI Plus - [1] Boiler TRIO UNI Plus - [1]](https://altepworld.com/storage/products/images/big/0d6PYaxm08kgjinVqCB0M5sjLWl0YKjMYWmbDgCE.png)

Solid fuel boiler TRIO UNI Plus

Universal long-burning boilers with a water-filled grate, compact dimensions and the ability to operate both with manual loading and automatic fuel supply. The convection part of the heat exchanger is located behind the furnace for convenient fuel loading.

The boilers are available in three versions:

- TRIO UNI Plus (kit) - a control unit withPID

- TRIO UNI Plus (manual kit) - with a manual loading kit, adapted for installation of the control unit withPID

- TRIO UNI Plus BK - a control unit with aPIDwith side inspection windows (80-600 kW).

- Easy installation of a pellet burner for automatic fuel supply - without changing the boiler design;

- Boiler material - high quality steel, 6-8 mm thick;

- Large furnace chamber, which allows the use of large firewood as fuel;

- Versatility - the ability to operate the boiler in the modes of manual fuel loading and automatic feeding;

- Insulated doors with double insulation - for safe operation and minimization of heat loss;

- Adapted for installation of a mechanical draft regulator (14-40 kW);

- Compact dimensions;

Characteristics of boilers 14-65 kW

| Parameter | Unit. | Norm for the TRIO UNI/TRIO UNI PLUS boiler | |||||

| Rated power of the boiler | kW | 14 | 20 | 30 | 40 | 50 | 65 |

| Heat exchanger area | м2 | 2,0 | 2,2 | 3,0 | 4,0 | 4,7 | 6,0 |

| Firebox dimensions | |||||||

| Depth | mm | 400 | 450 | 520 | 600 | 600 | 650 |

| Volume | dm3 | 75 | 90 | 135 | 170 | 200 | 275 |

| Water capacity of the boiler | л | 75 | 80 | 100 | 140 | 160 | 190 |

| Weight of the boiler without water | kg | 330 | 350 | 430 | 540 | 600 | 690 |

| Fuel gas temperature | °C | 100-180 | 100-180 | 100-180 | 100-180 | 100-180 | 100-180 |

| Recommended minimum water temperature | °C | 58 | 58 | 58 | 58 | 58 | 58 |

| Maximum water temperature | °C | 85 | 85 | 85 | 85 | 85 | 85 |

| Nominal operating water pressure | MPa | 0,15 | 0,15 | 0,15 | 0,15 | 0,20 | 0,20 |

| Electricity consumption, no more than | W | 85 | 85 | 85 | 105 | 160 | 160 |

| Connecting (external) dimensions of the hog | mm | 159 | 159 | 178 | 219 | 219 | 248 |

| Diameter of mains water connections (DN) | mm | 50 | 50 | 50 | 50 | 50 | 50 |

| Recommended chimney parameters | |||||||

| Cross-sectional area | cm2 | 201 | 201 | 248 | 377 | 377 | 452 |

| Inner diameter | mm | 160 | 160 | 180 | 220 | 220 | 250 |

| Height (minimum allowable) | м | 5 | 5 | 5 | 6 | 6 | 6 |

| Diameter of the pipe for the safety valve (DN) | mm | 15 | 15 | 15 | 15 | 20 | 20 |

| Diameter of the boiler water drain connection (DN) | mm | 15 | 15 | 15 | 15 | 20 | 20 |

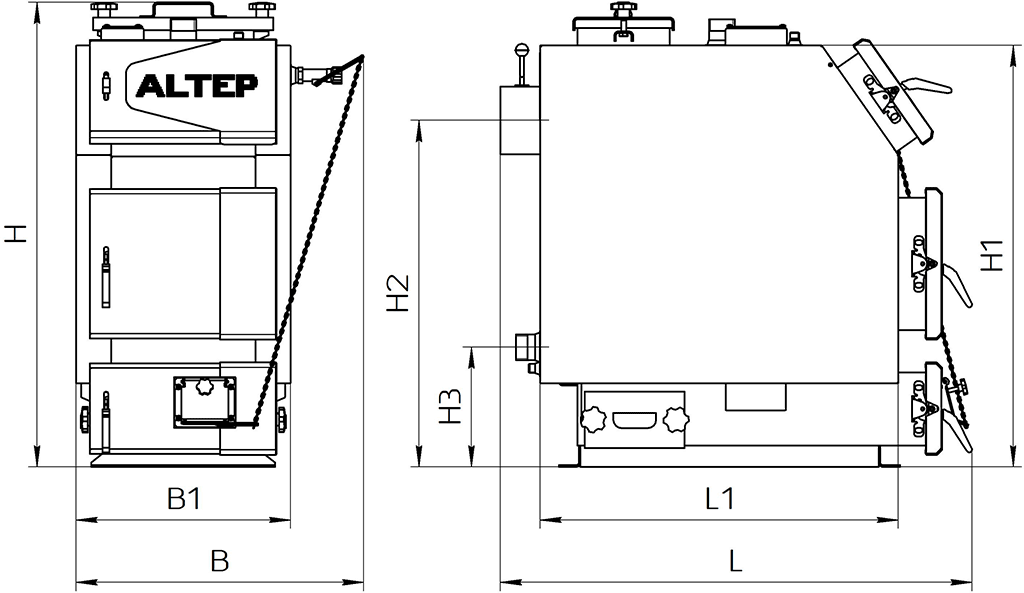

Overall dimensions of the TRIO UNI 14-40 kW boiler

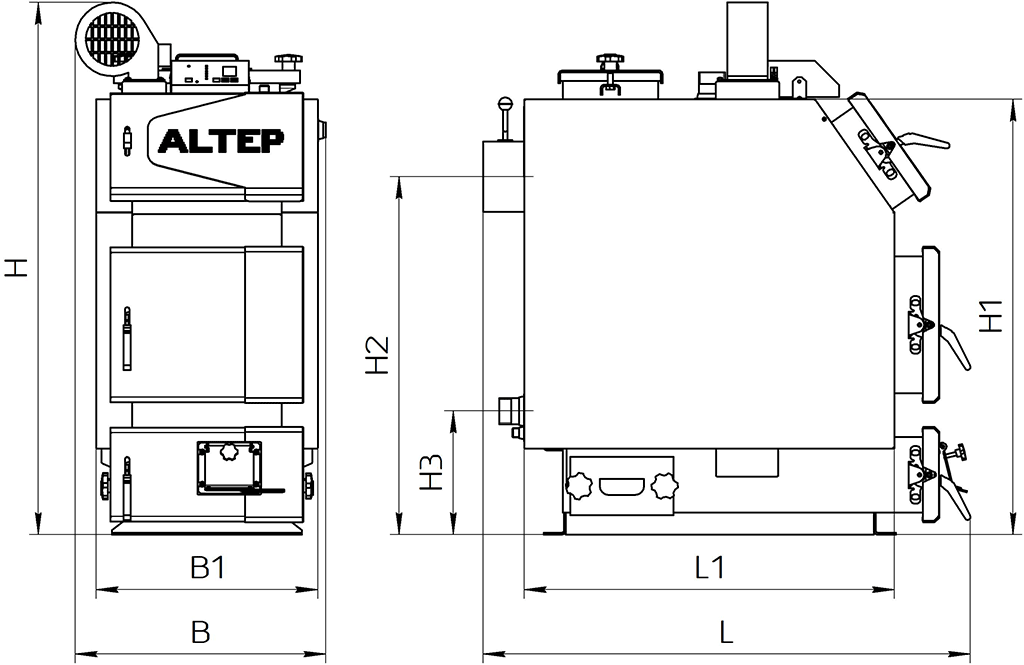

Overall dimensions of the boiler TRIO UNI Plus 14-40 kW

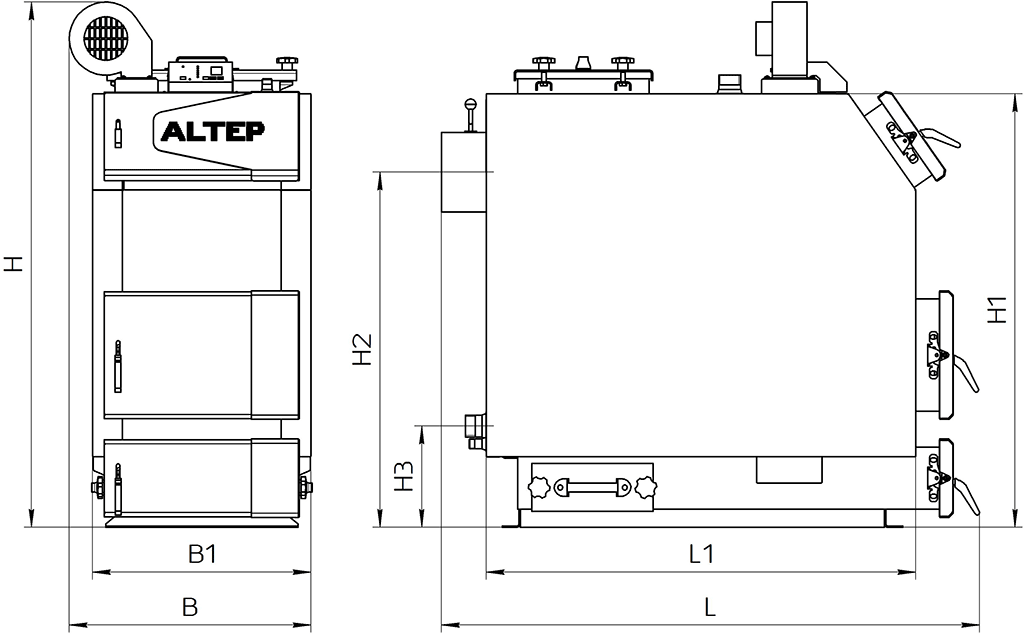

Overall dimensions of the TRIO UNI Plus boiler 50-65 kW

Overall dimensions of boilers 14-65 kW

| Parameter | Unit of measurement | Norm for the TRIO UNI/TRIO UNI PLUS boiler | |||||

| Overall dimensions of the boiler | kW | 14 | 20 | 30 | 40 | 50 | 65 |

| B | mm | 570/690 | 570/690 | 620/740 | 640/740 | 670 | 750 |

| B1 | mm | 500 | 500 | 550 | 550 | 600 | 680 |

| H | mm | 1210/1050 | 1210/1050 | 1310/1150 | 1400/1200 | 1460 | 1500 |

| H1 | mm | 990 | 990 | 1095 | 1145 | 1195 | 1245 |

| H2 | mm | 810 | 810 | 900 | 930 | 980 | 1030 |

| H3 | mm | 280 | 280 | 280 | 280 | 280 | 280 |

| L | mm | 840 | 890 | 960 | 1185 | 1185 | 1230 |

| L1 | mm | 880 | 930 | 1000 | 1225 | 1225 | 1275 |

Solid fuel boilers of the typeTRIO UNI Plus - long-term combustion. They are designed for heating domestic, industrial and other premises equipped with a central heating system, for preparing and supplying heat for technological needs. Power range:14-600 kW.

In the basic configuration, the boiler can be operated in the mode of manual loading of solid fuel. To switch the boiler to the automatic fuel supply mode, it is necessary to additionally install a door for the pellet burner, the burner itself and the fuel hopper. The boiler is equipped with a water grate. The multi-channel air supply system ensures long-lasting and even combustion of fuel from top to bottom. This advantage allows the use of different types of fuel, different sizes and fractions.

A special feature of the model is the placement of the heat exchanger in the rear part of the boiler, which significantly expands the power range. The vertical placement of the heat exchanger shelves minimizes the accumulation of unburned fuel particles, which allows the boiler to be cleaned once a week. Inspection doors are located on the top and on both sides of the boiler, which provides convenient maintenance of the equipment.

Boilers of the seriesTRIO UNI Plus are equipped with a fan and a control unit to automate the operation of the equipment.