Solid fuel boilers Trio Pellet

![Boiler TRIO Pellet - [2] Boiler TRIO Pellet - [2]](https://altepworld.com/storage/products/images/big/UmhilAdNfJ6O2oWoQPx4h1PUlMiBmJMOf29K7nl5.jpg)

![Boiler TRIO Pellet - [3] Boiler TRIO Pellet - [3]](https://altepworld.com/storage/products/images/big/Q0tWDMYQ1EU9Q4oN8yo14j7f9yO7LKWy7HamesnT.png)

![Boiler TRIO Pellet - [4] Boiler TRIO Pellet - [4]](https://altepworld.com/storage/products/images/big/LTuGodhNXkZFVcEsDAdRZ2rM1zjTFyPGnVEDT1Hb.png)

![Boiler TRIO Pellet - [5] Boiler TRIO Pellet - [5]](https://altepworld.com/storage/products/images/big/CCINgDijAvIW8lsyd7Jjb97lE1mIgIpTCUXWjwio.png)

![Boiler TRIO Pellet - [6] Boiler TRIO Pellet - [6]](https://altepworld.com/storage/products/images/big/XgRcA6G3GKnju9I8i2JqFaHVLDnqjXUIRndoToDm.png)

![Boiler TRIO Pellet - [7] Boiler TRIO Pellet - [7]](https://altepworld.com/storage/products/images/big/P0dCsOYhJlFvHpBkTw2ZtRvH4YAkEmekqP2bBLm0.png)

![Boiler TRIO Pellet - [8] Boiler TRIO Pellet - [8]](https://altepworld.com/storage/products/images/big/7Si3nkdQGxMILv5DUXEdwwqwkN3zMTnYXyYG6zpM.png)

![Boiler TRIO Pellet - [9] Boiler TRIO Pellet - [9]](https://altepworld.com/storage/products/images/big/LhTqw4V3HPiW5ExqR0W3wiCXVTxZKi2EBmEvK4uY.png)

![Boiler TRIO Pellet - [10] Boiler TRIO Pellet - [10]](https://altepworld.com/storage/products/images/big/rDmzo8dFKYe36aQsveazBuA8H4mhDLXxujePMlWV.png)

![Boiler TRIO Pellet - [1] Boiler TRIO Pellet - [1]](https://altepworld.com/storage/products/images/big/6mLz36jsAxbOiwh1EMSEgMRLNmsPMw2d2mdQ6QGG.png)

Solid fuel boilers Trio Pellet

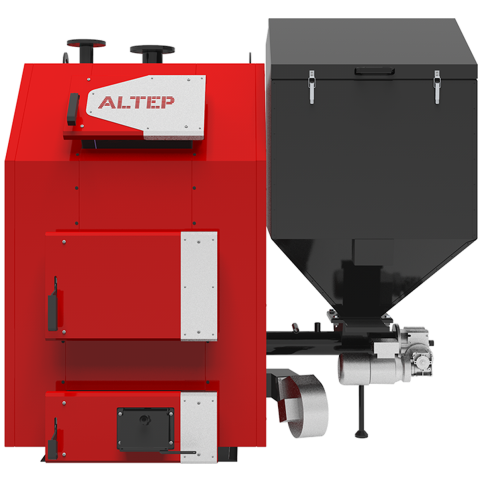

Boilers with automatic dosed fuel supply, designed for heating industrial premises and infrastructure facilities, are capable of operating on fractional fuel (pellets, coal, etc.). They are equipped with a European-made retort burner. The boiler can be easily switched to manual fuel loading mode. Safe operation is ensured by a boiler control unit and a non-volatile fire extinguishing system.

- Durability of the boiler - made of high quality steel, 6-8 mm thick;

- Automatic fuel supply;

- Self-cleaning function of the burner;

- Insulated doors with double insulation - for safe operation and minimization of heat loss;

- Unpretentious to fuel;

- Easy to maintain;

| Parameter. | Unit. | TRIO Pellet boilers | ||||||

| Rated power of the boiler | kW | 150 | 200 | 250 | 300 | 400 | 500 | 600 |

| Heat exchanger area | м2 | 13,1 | 16,5 | 24,1 | 27,2 | 36 | 41,0 | 46,2 |

| Efficiency, not less than | %</notranslate | 91 | 91 | 91 | 91 | 91 | 91 | 91 |

| Water capacity of the boiler | л | 365 | 425 | 585 | 655 | 800 | 900 | 1050 |

| Weight of the boiler without water | kg | 1500 | 1850 | 2300 | 2550 | 3800 | 4500 | 5000 |

| Fuel gas temperature | °C | 100-180 | 100-180 | 100-180 | 100-180 | 100-180 | 100-180 | 100-180 |

| Recommended minimum water temperature | °C | 58 | 58 | 58 | 58 | 58 | 58 | 58 |

| Maximum water temperature | °C | 85 | 85 | 85 | 85 | 85 | 85 | 85 |

| Nominal operating water pressure | MPa | 0,20 | 0,20 | 0,20 | 0,20 | 0,20 | 0,20 | 0,20 |

| Electricity consumption, no more than | W | 430 | 660 | 660 | 660 | 1320 | 1320 | 1320 |

| Connecting (external) dimensions of the hog | mm | 298 | 348 | 398 | 448 | 498 | 548 | 548 |

| Diameter of mains water connections (DN) | mm | 80(FL) | 100(FL) | 100(FL) | 100(FL) | 125(FL) | 125(FL) | 125(FL) |

| Recommended chimney parameters | ||||||||

| cross-sectional area | cm2 | 660 | 908 | 1194 | 1520 | 1885 | 2290 | 2290 |

| inner diameter | mm | 300 | 350 | 400 | 450 | 500 | 550 | 550 |

| height (minimum allowable) | м | 10 | 11 | 11 | 12 | 13 | 14 | 15 |

| Diameter of the fitting for the safety valve (DN) | mm | 50(FL) | 50(FL) | 50(FL) | 50(FL) | 50×2(FL) | 50×2(FL) | 50×2(FL) |

| Fan performance | m3/hour | 600 | 600 | 600 | 600 | 600×2 | 600×2 | 600×2 |

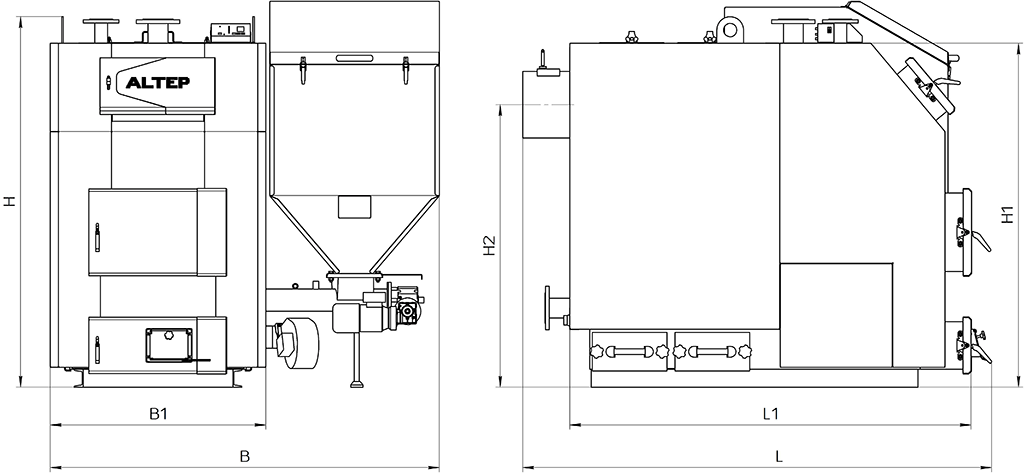

Overall dimensions of the TRIO Pellet 150 kW boiler

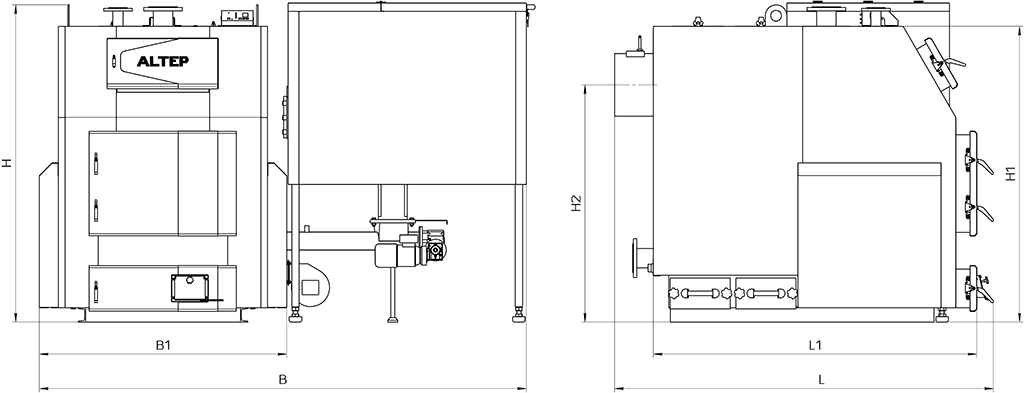

Overall dimensions of the TRIO Pellet boiler 200-300 kW

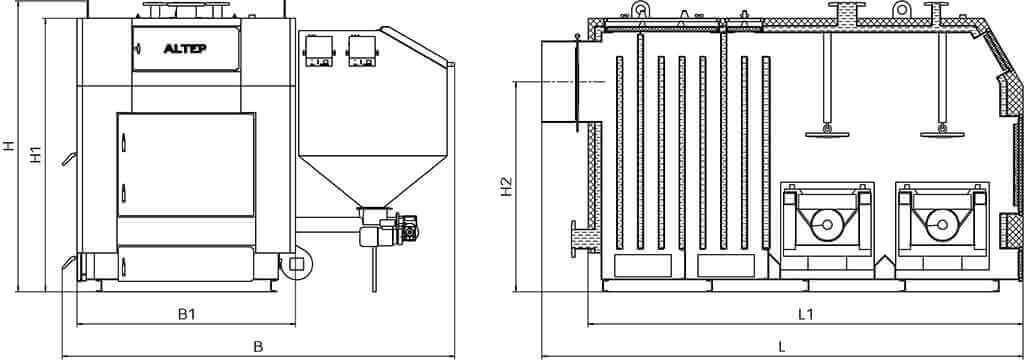

Overall dimensions of the TRIO Pellet boiler 400-600 kW

| Parameter | Unit of measurement | Pellet boilers TRIO Pellet | ||||||

| Overall dimensions of the boiler | kW | 150 | 200 | 250 | 300 | 400 | 500 | 600 |

| B | mm | 1750 | 2710 | 3170 | 3410 | 2650 | 2650 | 2750 |

| B1 | mm | 970 | 1380 | 1380 | 1380 | 1480 | 1480 | 1530 |

| H | mm | 1660 | 1760 | 1760 | 1860 | 1860 | 1960 | 1960 |

| H1 | mm | 1540 | 1640 | 1640 | 1740 | 1740 | 1850 | 1850 |

| H2 | mm | 1266 | 1316 | 1288 | 1364 | 1340 | 1415 | 1415 |

| L | mm | 2100 | 2110 | 2300 | 2380 | 3310 | 3350 | 3650 |

| L1 | mm | 1800 | 1800 | 2000 | 2080 | 2890 | 2930 | 3120 |

Boilers of the typeTRIOPellet - reliable long-burning, low-temperature boilers with an automatic fuel supply system. They are designed for heating domestic, industrial and other premises. Power range:150-600 kW.

The fuel for the boiler is automatically supplied to the retort burner by means of a screw feeder from the fuel tank located next to the boiler. The hopper can be placed on the left or right side. The boiler is equipped with a deflector, which ensures uniform heat distribution over the entire area of the heat exchanger, extending the operating period of the boiler.

A special feature of the model is the placement of the heat exchanger in the rear part of the boiler, which significantly expands the power range. The vertical placement of the heat exchanger shelves minimizes the accumulation of unburned fuel particles, which allows the boiler to be cleaned once a week. Inspection doors are located on the top and on both sides of the boiler, which provides convenient maintenance of the equipment.

Using the control panel, the user can adjust the fuel and air supply modes for high-quality and efficient fuel combustion. The fuel supply mechanism is equipped with an emergency fire extinguishing system.