Solid fuel boiler BIO

![BIO boiler - [2] BIO boiler - [2]](https://altepworld.com/storage/products/images/big/fxY5gc7bSsL3Ev9jr6NyQXt6Th3rMFFu5499FRje.jpg)

![BIO boiler - [3] BIO boiler - [3]](https://altepworld.com/storage/products/images/big/c7UrovuNIkhJn22IWovEZ6Iu0JigpU9IGqTvU5qR.png)

![BIO boiler - [4] BIO boiler - [4]](https://altepworld.com/storage/products/images/big/IBzs02Uihw7EyQACVUPo4Vvl25bXrGtdRc2txaZK.png)

![BIO boiler - [5] BIO boiler - [5]](https://altepworld.com/storage/products/images/big/qAu4wejMPArAUrom0V8dxpbsKJSi4LiUwIYmNGWx.png)

![BIO boiler - [6] BIO boiler - [6]](https://altepworld.com/storage/products/images/big/r2vzDMl1gzVj4B2HopGmQHjazYf4vE6KkfZZS1qP.png)

![BIO boiler - [1] BIO boiler - [1]](https://altepworld.com/storage/products/images/big/0a3Zh5j7ShXEHNYkDM3QrtxcQA2hx5ptBroVa1Ds.png)

Solid fuel boiler BIO

A solid fuel boiler with a heat exchanger of the heat-tube type. The fuel (wood chips, pellets, fine coal) for the boiler operation is dosed from the bunker using a screw mechanism. The chamotte furnace chamber provides high efficiency of the boiler and the most efficient high-temperature combustion of fuel. It is possible to operate the VIO boiler in the mode of manual fuel loading.

The boilers are available in three versions:

- BIO - boilers with automatic feeding, a fuel bunker is installed

- BIO UNI - boilers with manual fuel loading

- BIO - boilers with automatic feeding, a square fuel bunker is installed

- Durability of the boiler - made of high-quality steel, 6-8 mm thick;

- High working pressure of the heat carrier;

- Adapted for manual fuel loading;

- Insulated doors with double insulation - for safe operation and minimization of heat loss;

- Easy to maintain;

- Economical in operation - wood waste can be used as fuel;

| Parameter | Unit of measurement | Norm for the KVT-SHF boiler | |||||||||||||||

| Nominal heat output (power) of the boiler | kW | 95 | 150 | 200 | 250 | 300 | 400 | 500 | 600 | 700 | 800 | 1000 | 1200 | 1500 | |||

| Fuel | Wood waste, chips with a fraction from 5x5x5 mm to 15x35x80 mm, | ||||||||||||||||

| humidity no more than 30% (for humidity more than 30% it is recommended to use a rectangular hopper) | |||||||||||||||||

| Efficiency factor, not less than | %</notranslate | 86 | |||||||||||||||

| Depth of the firebox | 645 | 730 | 730 | 1130 | 1000 | 1000 | 1200 | 1310 | 1410 | 1610 | 1810 | 2010 | 2210 | ||||

| Water capacity of the boiler | м3 | 0,26 | 0,28 | 0,34 | 0,45 | 0,62 | 0,83 | 0,95 | 1 | 1,1 | 1,2 | 1,3 | 1,7 | 1,8 | |||

| Weight of the boiler without water and without fuel tank | kg | 1200 | 1250 | 1450 | 1800 | 2680 | 3330 | 3900 | 4000 | 4100 | 4500 | 4850 | 5550 | 5850 | |||

| Weight of the fuel hopper with a wiggle mechanism | kg | 465 | 480 | 810 | |||||||||||||

| Weight of a rectangular fuel hopper with a wiggle mechanism | kg | 780 | 810 | ||||||||||||||

| Fuel tank capacity (rectangular tank) | м3 | 1,5 (3) | 3 | ||||||||||||||

| The required flue gas flow | Pa. | 60-80 | |||||||||||||||

| Flue gas temperature at the boiler outlet | °C | 100-180 | |||||||||||||||

| Recommended minimum water temperature | °C | 58 | |||||||||||||||

| Maximum water temperature | °C | 85 | |||||||||||||||

| Nominal (maximum operating) water pressure | MPa | 0,3 | |||||||||||||||

| Test water pressure, max. | MPa | 0,45 | |||||||||||||||

| Electricity consumption, no more than | kW | 1,5 | 1,6 | 1,6 | 1,6 | 1,7 | 1,8 | 2,1 | 2,5 | 2,6 | 2,6 | 2,6 | 3,2 | 3,2 | |||

| Power supply voltage | 380 V (50 Hz) | ||||||||||||||||

| Overall and connection dimensions of the boiler | |||||||||||||||||

| Parameter. | Unit of measurement | Norm for the KVT-SHF boiler | |||||||||||||||

| 95 | 150 | 200 | 250 | 300 | 400 | 500 | 600 | 700 | 800 | 1000 | 1200 | 1500 | |||||

| Overall and connection dimensions of the boiler | B | 1360 | 1360 | 1440 | 1440 | 1490 | 1690 | 1690 | 1690 | 1730 | 1730 | 1730 | 1830 | 1830 | |||

| B1 | 1090 | 1090 | 1170 | 1170 | 1330 | 1530 | 1530 | 1530 | 1570 | 1570 | 1570 | 1610 | 1610 | ||||

| D | 298 | 298 | 348 | 398 | 448 | 498 | 548 | 548 | 548 | 548 | 548 | 598 | 598 | ||||

| H | 1840 | 1840 | 1990 | 1990 | 2300 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2750 | 2750 | ||||

| H1 | 1700 | 1700 | 1850 | 1850 | 2160 | 2360 | 2360 | 2360 | 2360 | 2360 | 2360 | 2610 | 2610 | ||||

| H2 | 1383 | 1384 | 1530 | 1530 | 1806 | 1931 | 1956 | 1956 | 1956 | 1956 | 1956 | 2186 | 2186 | ||||

| H3 | 402 | 403 | 402 | 402 | 403 | 403 | 403 | 403 | 413 | 413 | 413 | 653 | 654 | ||||

| L | 1890 | 1980 | 1980 | 2380 | 2480 | 2500 | 2720 | 2830 | 2920 | 3120 | 3320 | 3520 | 3720 | ||||

| L1 | 1045 | 1135 | 1135 | 1535 | 1535 | 1535 | 1735 | 1845 | 1955 | 2155 | 2355 | 2585 | 2785 | ||||

| L2 | 124 | 126 | 126 | 126 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 175 | 175 | ||||

| L3 | 762 | 848 | 848 | 1248 | 1220 | 970 | 1170 | 1282 | 1370 | 1570 | 1770 | 1930 | 2130 | ||||

| A | round hopper | 3600 | 3650 | 3750 | 3850 | 3950 | 4150 | 4200 | 4300 | 4350 | 4350 | 4350 | 4450 | 4450 | |||

| rectangular hopper | 3915 | 3915 | 4005 | 4005 | 4055 | 4255 | 4255 | 4255 | 4295 | 4295 | 4300 | 4375 | 4375 | ||||

| C | round hopper | 2200 | 2200 | 2200 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | |||

| rectangular hopper | 1565 | 1565 | 1565 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | ||||

| К | 2975 | 3025 | 3015 | 3265 | 3300 | 3300 | 3400 | 3455 | 3500 | 3600 | 3700 | 3800 | 3900 | ||||

| Diameter of the direct and return water pipes (DN) | mm | 65 | 65 | 65 | 65 | 80 | 80 | 80 | 80 | 100 | 100 | 100 | 125 | 150 | |||

| Recommended chimney parameters | cross-sectional area | cm2 | 660 | 660 | 908 | 1194 | 1520 | 1885 | 2290 | 2290 | 2290 | 2290 | 2290 | 2830 | 2830 | ||

| inner diameter | mm | 300 | 300 | 350 | 400 | 450 | 500 | 550 | 550 | 550 | 550 | 550 | 600 | 600 | |||

| height (minimum allowable) | м | 7 | 9 | 9 | 10 | 12 | 13 | 14 | 15 | 18 | 21 | 27 | 24 | 30 | |||

| Diameters of the connections for the safety valve (DN) | mm | 50 | 50 | 50 | 50 | 50 | 2×50 | 2×50 | 2×50 | 2×50 | 2×50 | 2×65 | 2×65 | 2×65 | |||

| Required actuation pressure of the safety valve | MPa | 0,35 | |||||||||||||||

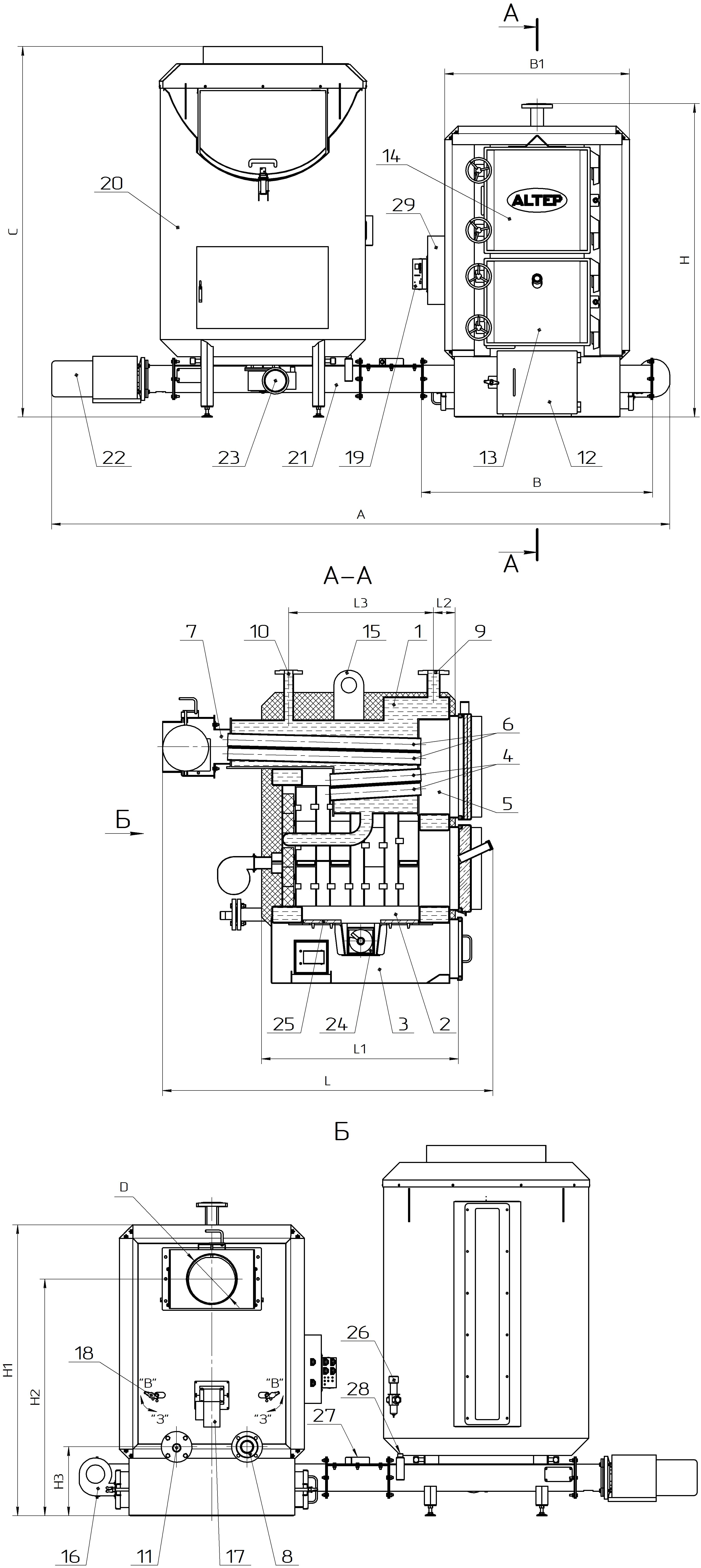

Dimensions of the Altep BIO boiler

| Parameter | Unit of measurement | Norm for the KVT-SHF boiler | |||||||||||||||

| 95 | 150 | 200 | 250 | 300 | 400 | 500 | 600 | 700 | 800 | 1000 | 1200 | 1500 | |||||

| Overall and connection dimensions of the boiler | B | 1360 | 1360 | 1440 | 1440 | 1490 | 1690 | 1690 | 1690 | 1730 | 1730 | 1730 | 1830 | 1830 | |||

| B1 | 1090 | 1090 | 1170 | 1170 | 1330 | 1530 | 1530 | 1530 | 1570 | 1570 | 1570 | 1610 | 1610 | ||||

| D | 298 | 298 | 348 | 398 | 448 | 498 | 548 | 548 | 548 | 548 | 548 | 598 | 598 | ||||

| H | 1840 | 1840 | 1990 | 1990 | 2300 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2750 | 2750 | ||||

| H1 | 1700 | 1700 | 1850 | 1850 | 2160 | 2360 | 2360 | 2360 | 2360 | 2360 | 2360 | 2610 | 2610 | ||||

| H2 | 1383 | 1384 | 1530 | 1530 | 1806 | 1931 | 1956 | 1956 | 1956 | 1956 | 1956 | 2186 | 2186 | ||||

| H3 | 402 | 403 | 402 | 402 | 403 | 403 | 403 | 403 | 413 | 413 | 413 | 653 | 654 | ||||

| L | 1890 | 1980 | 1980 | 2380 | 2480 | 2500 | 2720 | 2830 | 2920 | 3120 | 3320 | 3520 | 3720 | ||||

| L1 | 1045 | 1135 | 1135 | 1535 | 1535 | 1535 | 1735 | 1845 | 1955 | 2155 | 2355 | 2585 | 2785 | ||||

| L2 | 124 | 126 | 126 | 126 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 175 | 175 | ||||

| L3 | 762 | 848 | 848 | 1248 | 1220 | 970 | 1170 | 1282 | 1370 | 1570 | 1770 | 1930 | 2130 | ||||

| A | round hopper | 3600 | 3650 | 3750 | 3850 | 3950 | 4150 | 4200 | 4300 | 4350 | 4350 | 4350 | 4450 | 4450 | |||

| rectangular hopper | 3915 | 3915 | 4005 | 4005 | 4055 | 4255 | 4255 | 4255 | 4295 | 4295 | 4300 | 4375 | 4375 | ||||

| C | round hopper | 2200 | 2200 | 2200 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | |||

| rectangular hopper | 1565 | 1565 | 1565 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | ||||

| К | 2975 | 3025 | 3015 | 3265 | 3300 | 3300 | 3400 | 3455 | 3500 | 3600 | 3700 | 3800 | 3900 | ||||

| Diameter of the direct and return water pipes (DN) | mm | 65 | 65 | 65 | 65 | 80 | 80 | 80 | 80 | 100 | 100 | 100 | 125 | 150 | |||

| Recommended chimney parameters | cross-sectional area | cm2 | 660 | 660 | 908 | 1194 | 1520 | 1885 | 2290 | 2290 | 2290 | 2290 | 2290 | 2830 | 2830 | ||

| inner diameter | mm | 300 | 300 | 350 | 400 | 450 | 500 | 550 | 550 | 550 | 550 | 550 | 600 | 600 | |||

| height (minimum allowable) | м | 7 | 9 | 9 | 10 | 12 | 13 | 14 | 15 | 18 | 21 | 27 | 24 | 30 | |||

| Diameters of the connections for the safety valve (DN) | mm | 50 | 50 | 50 | 50 | 50 | 2×50 | 2×50 | 2×50 | 2×50 | 2×50 | 2×65 | 2×65 | 2×65 | |||

| Required actuation pressure of the safety valve | MPa | 0,35 | |||||||||||||||

Solid fuel boilers of the typeBIO - fire tube, long-burning. Designed for heating industrial buildings in automatic mode. Power range:95-1500 kW.

The fuel for the boiler is supplied automatically by a screw device from the fuel bunker located next to the boiler. The fire chamber equipped with chamotte stone contains ceramic catalysts that ensure high efficiency of the boiler and make its operation as efficient as possible. The design of the boiler provides for layered combustion of fuel. This allows for a significant reduction in heating costs. The equipment is equipped with an emergency fire extinguishing system. The design of this type provides for the installation of a hopper with a fuel supply mechanism both on the left and right sides.

Possible operation of the boilerBIO in the mode of manual loading of solid fuel.

Second column