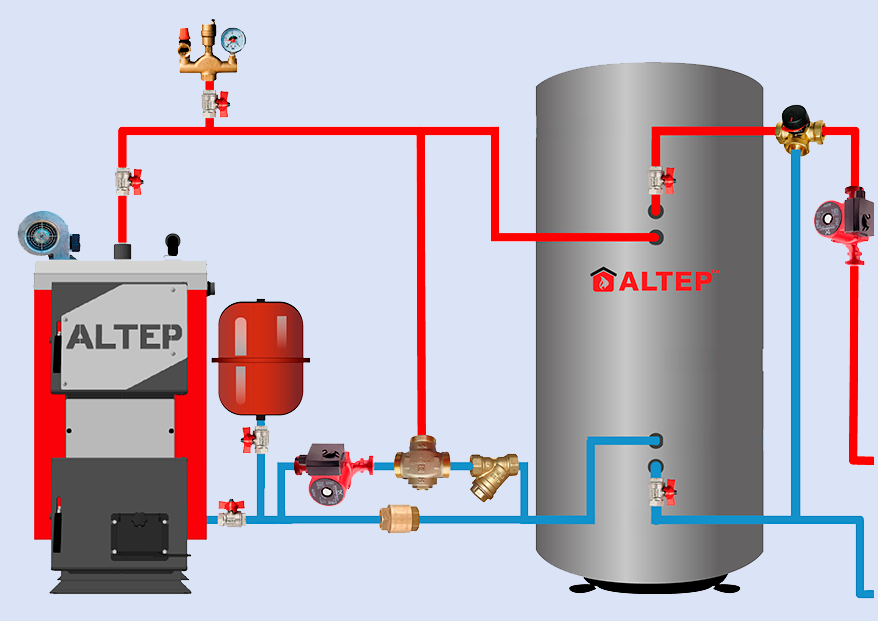

Connection diagram of the buffer tank to the solid fuel boiler

Heating is always a hot topic, given the rise in tariffs. And lately, more and more often consumers of solid fuel equipment are encouraged to install a buffer tank in the system. This is really a huge advantage in saving money and time for the maintenance of solid fuel equipment. It is ideal to connect the buffer tank to the boiler at the same time when installing a solid fuel boiler.

A solid fuel boiler and a heat accumulator in tandem have their advantages in heating. You can have the simplest solid fuel boiler, without modern modifications, but with the use of a tank in the system, its operation will give a head start to any long-burning boiler, or at least will not be inferior in the comfort of maintenance and will use heat efficiently, reduce the number of approaches to the combustion chamber and fuel costs.

The main reasons for connecting a buffer tank:

- The need to save costs;

- Increase in boiler operation on one load;

- Increase heat transfer;

- Remove the cause of boiler overheating;

- To accumulate heat;

- Use as a boiler.

And here the question often arises: "How to connect a heat accumulator to a boiler?"

To ensure safe installation of the buffer tank and efficient operation of the heat accumulator, you need to know some of the connection nuances. We'll talk about them below.

How to connect a buffer tank?

First of all, it is worth considering that the buffer tank is quite large and it is ideal to prepare the room for it at the design stage of the building. It is also better to install a solid fuel boiler with a buffer tank at once. Based on this, manufacturers began to produce them round and flat, which makes it easier to place them in a finished building, where there may not be enough space.

To connect a heat accumulator in a heating system, it is important to correctly calculate the capacity of the tank. That's why there is a special calculation formula.

Q = m * cp * (T2-T1), in which

- m is the mass of the coolant used in the tank;

- cp - specific heat capacity of the liquid accumulated in the heat accumulator;

- T2 and T1 are the average temperature of the coolant in the tank before and after heating.

There is also a calculation of the volume of the buffer tank. It is customary to consider the volume in the ratio of 30-50 liters of capacity per 1 kW of boiler.

What is important to know during installation:

- The vertical buffer tank may only be connected in rooms with a positive temperature.

- Installation and commissioning must be performed by a specialized company.

- Use water as a coolant.

- After the first startup, check the joints for leakage.

- A small amount of water (condensation) may appear from the heat exchangers during the first start-up.

- Install removable thermal insulation at the last stage of work.

- If there is a possibility of freezing, protect the tank from low temperatures or drain it completely.

- The heat accumulator must be grounded in accordance with the requirements of NPATO 40.1-1.21-98 "Rules for the safe operation of consumer electrical installations". Grounding is carried out through a special M8x25 bolt located at the bottom of the heat accumulator.

- It is best to insulate the buffer container as well. This will allow for better heat accumulation and prevent burns.

Sequence of installation of tank insulation:

- Removable insulation is exposed to ambient temperatures. When installing in a cold room, it is necessary to heat the insulation to 20-25°C.

- Insulation must be worn during installation and before connecting the circuits.

- During installation, unroll the insulation and stretch it over the tank so that the holes in the casing coincide with the branched nozzles. Smooth out the insulation so that it conforms to the shape of the tank and the zipper can be easily fastened. Carefully fasten the zippers from top to bottom. Do not force the zipper.

- Solid fuel boiler wiring requires technical knowledge and precautions. Therefore, it is always better to contact specialists who are familiar with the system and have studied the best connection methods in practice. They know how to properly connect the heat accumulator and make the equipment work efficiently.

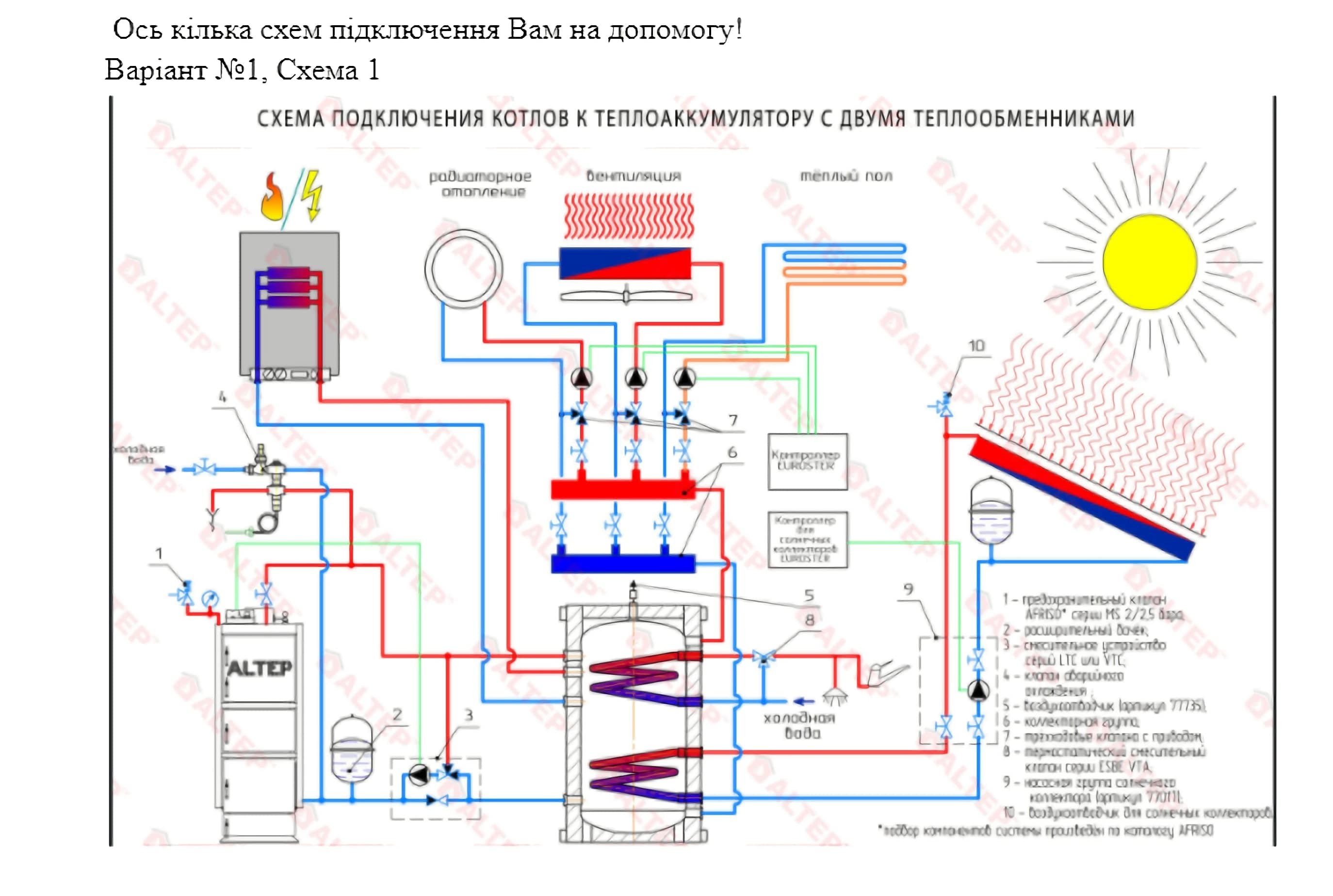

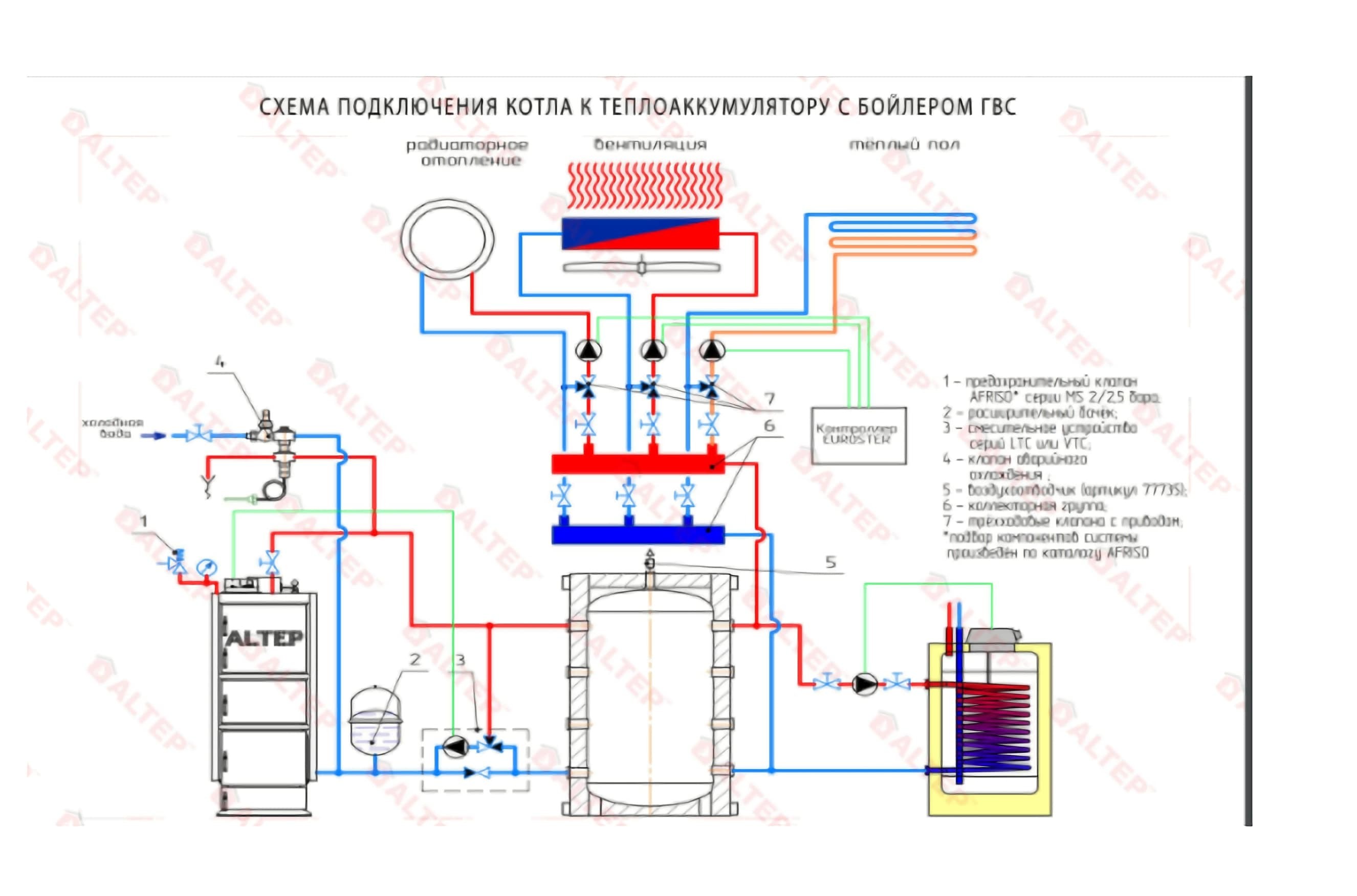

Here are some schemes for connecting a heat accumulator to a solid fuel boiler!

Option 1, Scheme 1

Option #2 Scheme 2

I hope that we have answered the question "How to connect a heat accumulator?" and that it was useful to you! The easiest way is not always the most effective. You need to take a broader view and make economic calculations.

Don't forget about safety precautions and that a good manufacturer always describes important information in the product manual. It will also help you to set up the equipment correctly. Therefore, the information from the manufacturer should not be ignored! And then the connection will be easier!