How to connect underfloor heating to the boiler

Recently, underfloor heating has been increasingly used for space heating. For this heating option to be effective, you need to figure out how to connect the underfloor heating to the boiler. After all, the reliability, safety and efficiency of the equipment will depend on this.

What problems can be encountered when connecting?

Despite the convenience and efficiency of underfloor heating, some problems may arise when it is connected to a solid fuel boiler:

- Unlike gas-fired equipment, solid fuel equipment may not have an automatic coolant circulation control system. Therefore, to ensure a stable temperature of the coolant supply, it is necessary to additionally install a circulation pump.

- Even if the circulation pump is installed, it is possible that it will stop. This can happen if it breaks down or there is a power outage. As a result, the coolant inside the system may boil. And an increase in pressure in the system can lead to an accident. Even if the boiler is able to withstand high temperatures and pressures, if the temperature of the coolant rises to 100 degrees or more, plastic pipes may be damaged.

Therefore, when connecting underfloor heating to a solid fuel boiler, it is important that the heat transfer process is continuous.

Ways to connect water floor heating to a solid fuel boiler

There are several ways to connect underfloor heating to a solid fuel boiler. Each of them has its own characteristics.

Connection diagram with heat storage

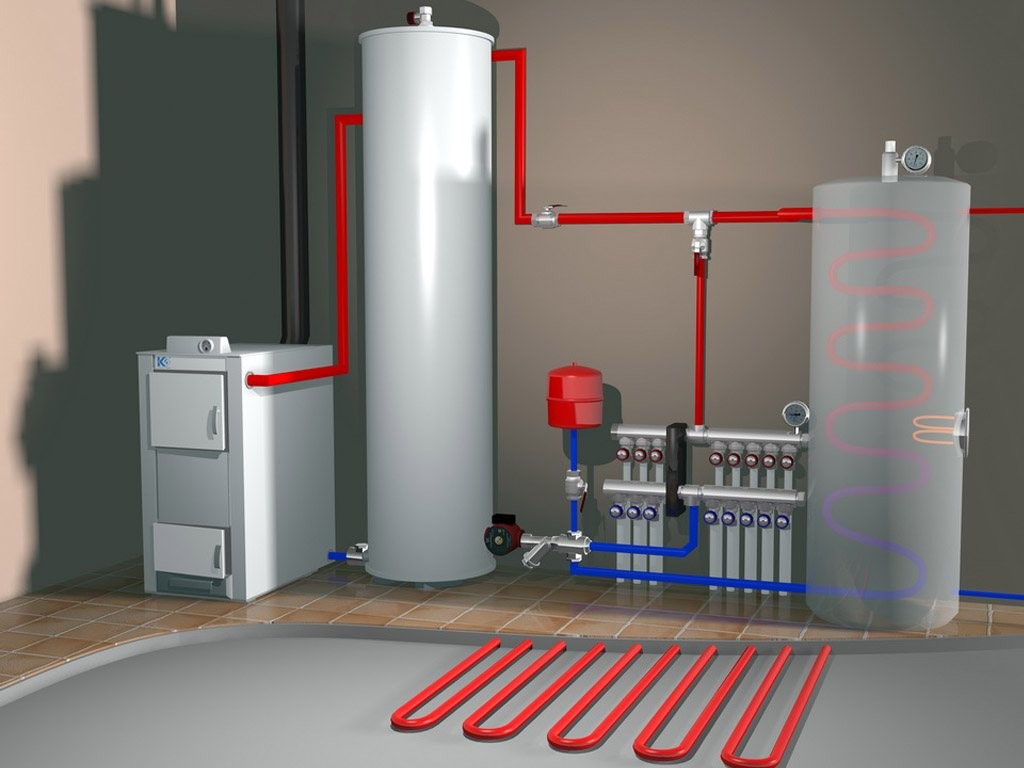

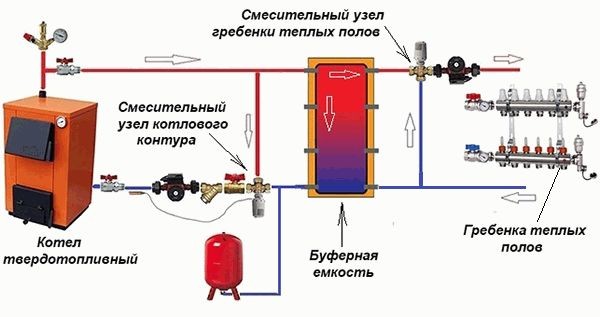

To make a water floor heating system powered by a solid fuel boiler as reliable and efficient as possible, a heat accumulator is installed in the system. The expansion tank will compensate for the expansion of the liquid inside the system. A distribution comb is installed in the system to ensure the regulation of the coolant.

In this case, the heat accumulator will absorb excess heat and provide protection against elevated temperatures by regulating the temperature of the coolant supply to the circuit. By using a buffer tank, you can further save on fuel by reducing its consumption.

When choosing this connection option, you should keep in mind that:

- Additional space is required for mounting, connecting and maintaining the buffer tank.

- Installing a heat accumulator requires additional costs. Depending on the volume of the tank, its cost varies from $600 to $1,000.

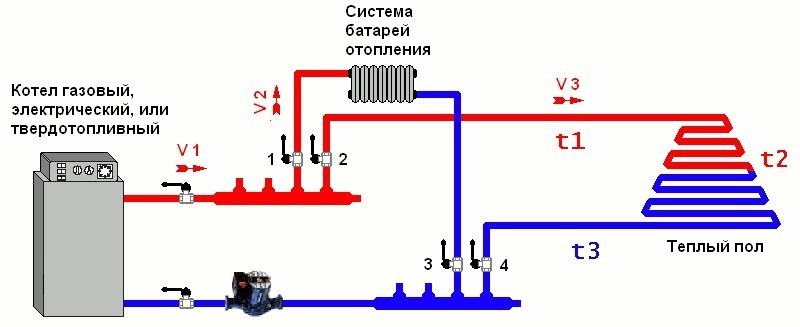

Connection diagram with additional radiators

Due to the lack of free space for installing an expansion tank or lack of finances, it is sometimes impossible to use the previous connection option. In this case, the method of dilution with a cast iron radiator is used. Its main task is to remove excess heat.

For example, when leaving the boiler, the temperature of the coolant can reach 75 degrees. At the same time, it will not exceed 40 degrees at the radiator outlet. In order to use heat rationally, it is necessary to think in advance about the location of the cast iron battery. This will avoid heat loss.

This method is used infrequently because it requires constant monitoring of the coolant temperature in the system.

If you are in doubt about which option is right for you, you should seek the help of a professional. He will select the best way to connect a warm floor to a TT boiler, taking into account all the nuances.