What is a heat accumulator and why is it needed?

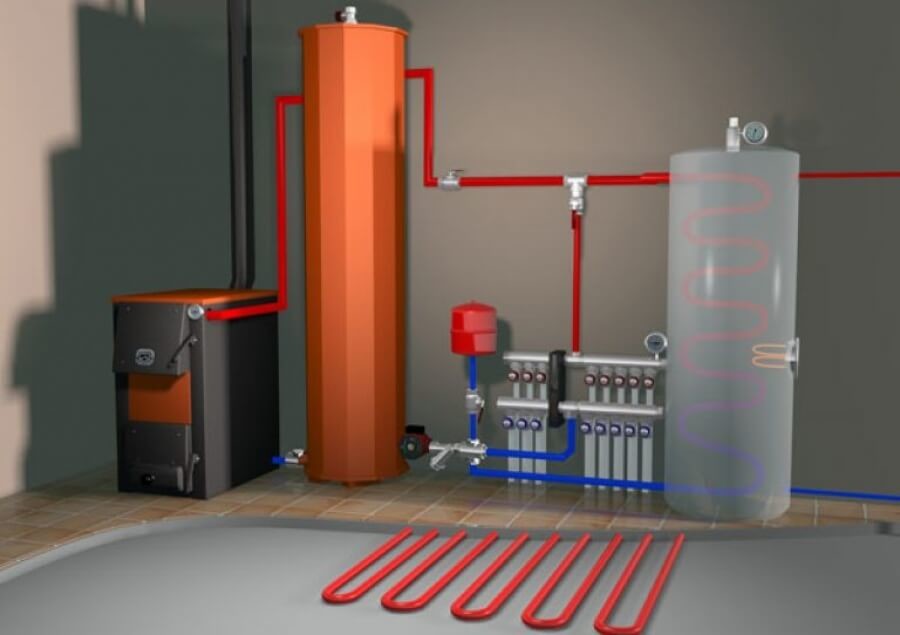

When designing a heating system with a solid fuel boiler, many people are faced with the question of how to calculate the heat storage tank for heating. A heat accumulator is a container designed to accumulate hot coolant. Usually, it is a steel tank with a connection to the circuit, additionally insulated and lined with a casing.

The use of a heat accumulator in a heating system has many advantages. First of all, it extends the periods between new firewood and ensures optimal operation of the equipment.

Why do you need a heat storage device?

The heat accumulator performs several functions at once:

- accumulation of thermal energy for its further transfer to the heating system;

- protection of the boiler from excessive heating by absorbing overheated coolant;

- increase in boiler efficiency due to complete combustion of fuel in the furnace;

- the ability to use different heat sources simultaneously;

- the possibility of providing hot water supply to the house through the use of a buffer tank.

How does a heat storage device for heating work?

The operation of a heat storage device is based on the heat capacity of water. Whatever boiler is used in the heating system, it cannot operate continuously. At first, it is heated to maximum performance, after which it is turned off. It is during the period when the boiler is off that the heat accumulator transfers the accumulated heat to the room.

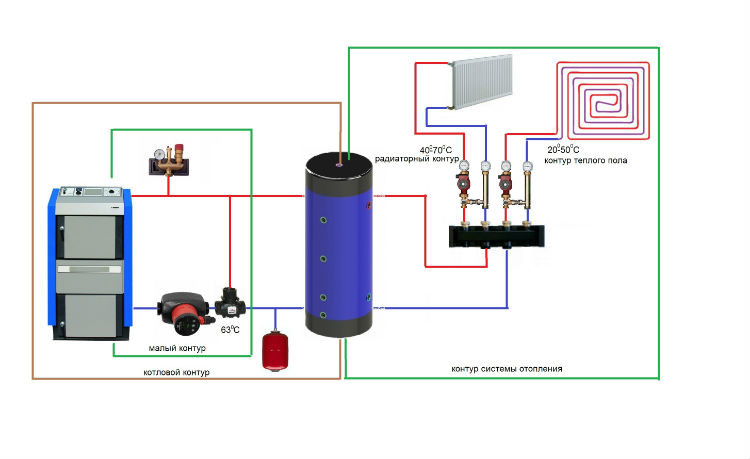

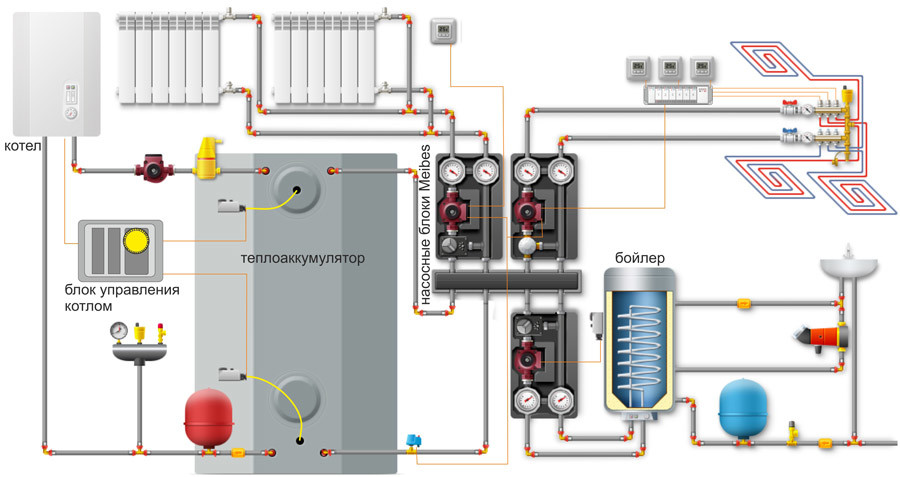

During boiler operation, hot water accumulates in the buffer tank. After the water in the radiators cools down, it is replaced with a portion of hot water from this tank. The heat accumulator in the heating system must be used with a mixing unit, which is installed behind the heat accumulator. The mixing unit is a unit that sets the temperature on the radiators. A mechanical (or servo-operated) three-way valve and a pump are used as a mixing unit.

The pump is connected to the network all the time, its task is to create a direction and push the coolant through the system. Thus, if there is a heat accumulator in the heating system, it is necessary to load the boiler furnace with fuel, set the boiler automation to 85 degrees and burn the fuel at this temperature. Check the temperature of the heat accumulator.

The minimum effective temperature of the heat accumulator is 75 degrees, and it is better to warm up the heat accumulator to a temperature of 80-82 degrees. Make sure that there is no fuel left in the firebox, the temperature in the heat accumulator is 75-82 degrees, and then stop the supercharging fan (press the Stop button).

Further hot water is added to the heating system from the heat accumulator. The duration of autonomous operation depends on the heat loss of the building and the amount of water in the buffer tank. When the temperature drops to 52-55 degrees, it is necessary to load a new portion of fuel and burn it at a temperature of 85 degrees.

In this way, two or more pumps are used simultaneously for a heat storage heating system.

Water heated by the combustion of fuel in the boiler enters the heat accumulator. Then it is distributed to radiators, from which the liquid again enters the reservoir, from where it is transferred to the boiler for heating. So, even if the boiler is off, there is a certain supply of heated coolant in the buffer tank. From here, it enters the heating system to heat the room.

How to calculate the heat accumulator for a solid fuel boiler?

A buffer tank, or heat accumulator, is a rather large container. It is important to take this into account at the design stage of the building. To calculate the volume of the tank, the ratio of 30-50 liters for each kW of boiler power is observed.

A formula is also used for this purpose:

Q = m * cp * (T2-T1), in which

m is the mass of the coolant used in the heat accumulator;

cp - specific heat capacity of the substance accumulated in the heat accumulator;

T2 and T1 are the average temperatures of the heat carrier in the heat accumulator before and after heating.

Regardless of which methodology is used to calculate the heat accumulator, it is important to follow certain rules:

- the longer the heat transfer medium consumption, the greater the volume; the nominal pressure cannot be less than the maximum operating pressure;

- when using a DHW heating system and a buffer tank, a safety valve and an expansion tank must be installed.

Conclusion.

A heat accumulator is an important and useful device in a heating system with a solid fuel boiler. Its use can increase the productivity of the equipment and extend its service life.

Also, the client will save fuel by 30-35%, the boiler operates only in the first mode (combustion) with an efficiency of more than 90%, the boiler heat exchanger, chimney are less prone to contamination by combustion products, the boiler needs to be heated in the morning and, if necessary, in the evening at night, spending 1.5-2 hours on it.

But for the buffer tank to work as efficiently as possible, it is important to calculate its volume correctly.