How to burn coal properly

Inefficient combustion of coal and wood is so widespread that it is considered the norm.

When burning, there must be smoke - every user with experience will confirm, because for many years this was the only way to burn. Fortunately, there are more efficient methods that help to burn coal and wood without smoke, stench and tar.

Regardless of how old and dirty your boiler is, whether you heat with cheap or expensive fuel, efficient fuel combustion will save you a lot of time and nerves and eliminate many boiler room problems, as most of them are the result of improper combustion techniques.

Smog is a fuel floating in the air!

Stench and thick gray smoke are a constant element of winter. More and more people are saying it's bad. But no one talks about the fact that smoke is fuel flying into the air.

Smoke is unburned gases that are released from each type of coal and wood when it is heated.

This is not just smoke, but part of the fuel - each ton of coal contains 300 kg of gases, and a ton of wood contains more than 700 kg! The problem is that these gases are burned only at temperatures of 400-500C. At the right temperature, the gases burn, so the smoke turns into almost transparent vapors. This is the correct economical combustion of coal and wood.

Unfortunately, most users are wasteful with fuel, loading a large amount of fuel directly into coal.

The temperature in a boiler filled with a pile of cold fuel is too low to burn the gaseous component of the fuel. Therefore, gray clouds of suffocating gas - coal dust and unburned wood fuel gases - fly up the chimney.

Problems associated with improper combustion of coal and wood:

- large amounts of soot and tar;

- chimney clogging;

- gas explosions;

- tar formed on the walls of the heat exchanger and chimney.

And above all, fuel consumption! In just one year, you will burn a ton, two or more than you really need!

Economical combustion - how is it done?

There is nothing new in the economical combustion of coal and wood. It is the creation of conditions in the boiler under which the fuel gases can be burned, and (almost) transparent vapors should go into the chimney. There are several methods, which are shown in the following illustrations.

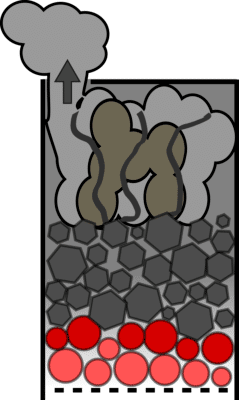

The figure below shows which methods are suitable for different types of boilers and furnaces.

The vast majority of boilers and stoves on the market (including fireplaces) are top-burning stoves - the smoke exits at the top of the heat exchanger. In such boilers, all three clean-burning methods can be used, with top-down combustion being preferred. In top-bottom combustion boilers, it is also possible, but, as a rule, top-down combustion is difficult.

Is it worth changing anything? Of course, because proper combustion will save you a significant - approx. 30% - the amount of fuel that costs a lot of money today. Calculate how much fuel you need to heat your home and compare the consumption - find out how much you can save.

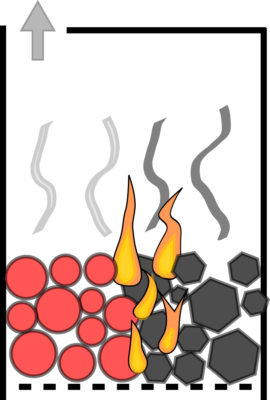

Adding fuel in small portions

It is only necessary to change your habits a little, to refuse to burn fuel from below, and your boiler's performance will improve.

The easiest way to get rid of smoke is to add fuel in small portions.

Small portions are a relative concept; there should be enough fuel to ignite without extinguishing (cooling) the combustion center. The more heat there is on the grate, the more intense the combustion center, and the more fuel can be loaded without the risk of "damping the flame". With the right portion of fuel, the worst thing that can come out of the chimney is translucent black smoke. There should be no thick gray smoke and no tar overgrowth in the chimney.

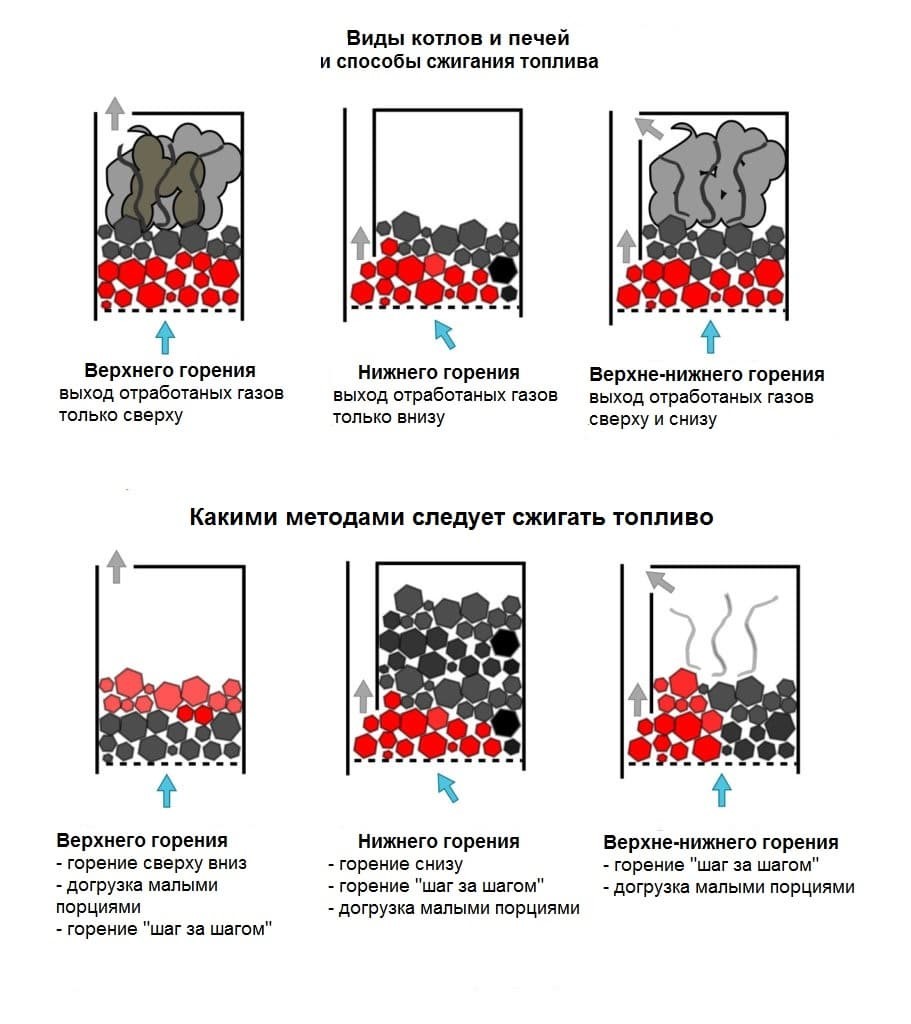

Combustion "step by step"

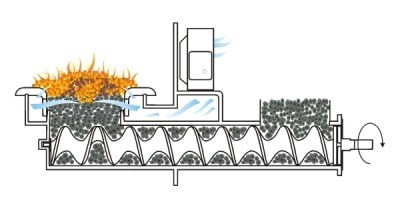

Side-by-side combustion can also be called "step-by-step" combustion, because in this case the combustion center moves in a horizontal direction. This method is a kind of compromise between top burning and typical bottom burning. It ensures continuous combustion by adding small portions, not quite clean, but still much better than when adding a large layer of fresh fuel.

How does combustion work?

The "step-by-step" combustion begins with the ignition of a small amount of fuel on the grate. When this part of the fuel burns out, the coals are moved to the back of the boiler, and the next portion of fuel is placed so that there is contact with the heat, but the fuel should not cover it.

Fresh fuel in these conditions does not heat up as quickly as when burned from below, because hot exhaust gases do not pass through the bed. Instead, the fire gradually engulfs the entire bookmark and releases volatile substances from the fuel, which have the ability to burn at high temperatures.

Comparison with other combustion methods

Step-by-step combustion is an alternative between the other two combustion methods.

Compared to burning from below, it is much better. Even the addition of large amounts of fuel does not cause "clogging" of the combustion hearth and prolonged smoke.

Compared to burning on top, this method is slightly worse, since not all volatile substances released from the fuel pass through the coal layer and burn out accordingly. The situation is, however, much better than when the same amount of fuel is placed on top of the coals.

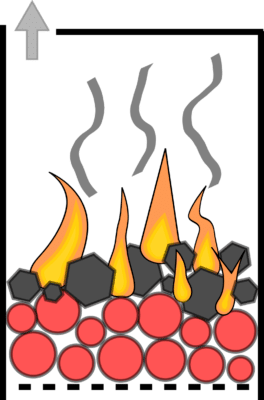

Burning from top to bottom

Compared to the traditional method of combustion, it is the cleanest and most efficient way of combustion.

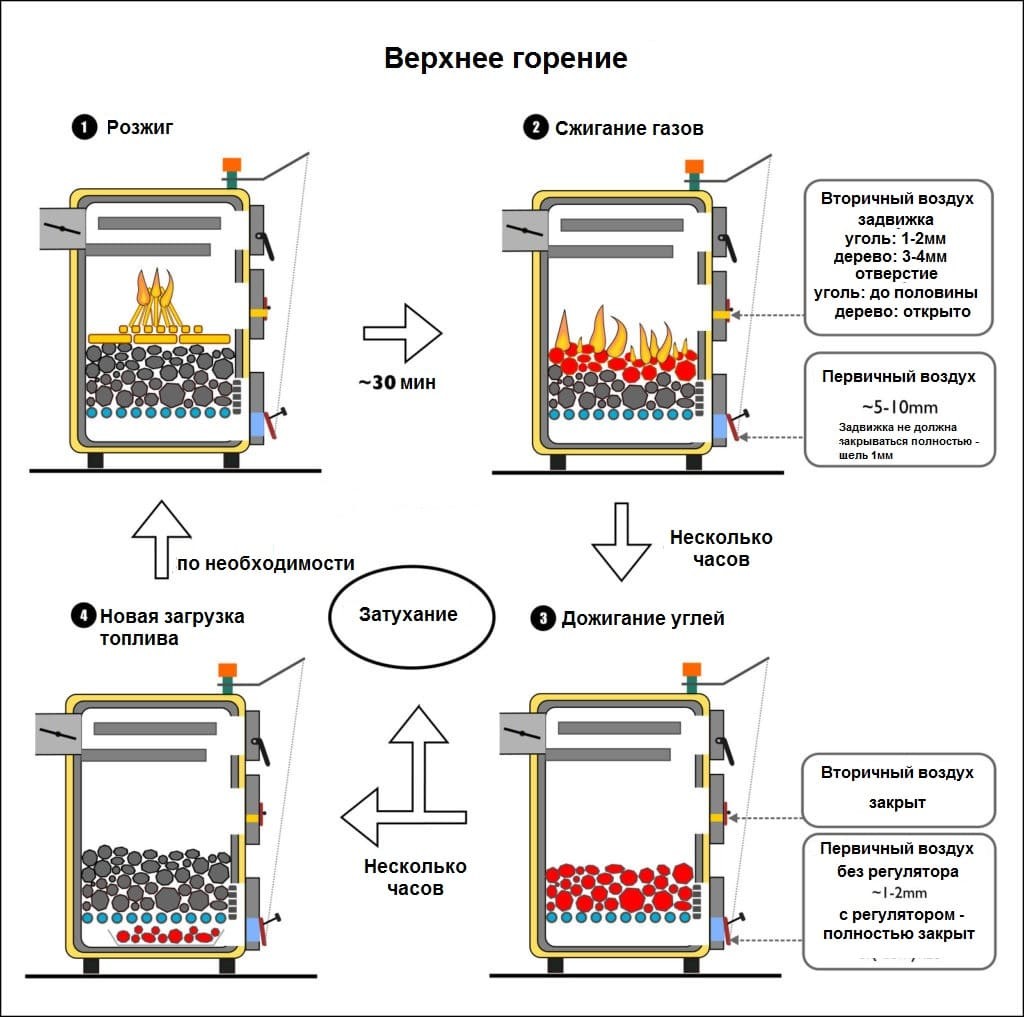

How the top burning is carried out

The task is to move the combustion center to the top of the furnace. The design of the boiler does not change, the air passes from the grate upwards. But now the combustion center slowly sinks down and the smoke from the cold fuel layer must pass through the fire, where it almost completely burns out. Almost transparent smoke is observed at the chimney outlet, which indicates efficient fuel combustion.

The entire combustion cycle is shown below. Top combustion is a cyclical process, i.e. the fuel is put in, ignited from above and completely burns out, only after that the next fuel is put in. The whole process is quite simple and the user only needs to change their habits a little.

In the same way as with top burning, but on a smaller scale, burners in boilers with a feeder work and therefore such boilers burn fuel cleanly and efficiently.

Test results: less smoke - less emissions

- Existing research in Western Europe shows that top-burning stoves and wood-burning fireplaces reduce particulate matter emissions by more than 50%.

- Thousands of people who have been using the top-burning principle for many years can attest to the noticeable fuel savings (approx. 30%).

Is top burning safe?

The top-burning method itself does not create new risks compared to the classical use of boilers and furnaces (and even slightly reduces the problem of gas explosion or chimney fire). On what basis can we make such a statement?

- More than ten years of intensive use of this particular method in Poland on various boilers have not revealed any known problems;

- top combustion is widely used in Western Europe;

- some of the upper-burning boilers that mention this particular combustion method in their instructions are indistinguishable in design from those that have no records of this - the problem is not technical, but in the mentality of manufacturers.

The method itself is not complicated, but you need to be very careful not to do anything you are not sure about. It will actually help to identify problems arising from installation errors or negligence in the operation of the heating system, chimney and boiler itself that have not yet been detected.

The main risk with top burning arises when too much fuel is loaded. If the boiler is not airtight or if the power is cut off at the time of firing, the consequences can be more serious than a normal temperature rise or boiling.

In a properly installed heating system, this is safe, but not all systems are made correctly.

The most important point is the relative tightness of all boiler doors andCOMPETENT SELECTION OF THE BOILER IN TERMS OF POWER.